SEIMITU WAVE AR1260

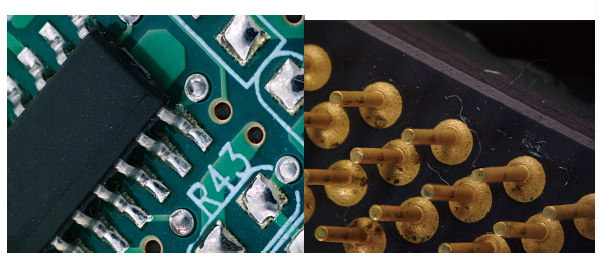

High sensitivity and high definition image with cooling Peltier

It was installed cooling system of Peltier element into image sensor. By keeping the CCD temperature cool, it can cut dark noise generated when it takes photo of extreme dark object. Also, it makes the resolving power for subtle light improve simultaneously. Furthermore, by parallel use of above system and Charge Shutter-Function which is standard equipment of AR1260, they demonstrate power for photographing observation or photofluorography.

* Charge Shutter Function of AR1260 :

It’s possible to observe brightly after letting shutter speed open at maximum 136 second.

High definition image with big size image sensor.

AD1260 adopt 2/3” CCD which is largest one in microscope business world. Image quality was improved so much because light quantity could have enough space as image sensor became wider enough. The CCD makes further high definition real image quality by combing high resolution pixel shift technology. In addition to above, if same range of optical magnification microscope lens is used, it catch wider visual field than usual microscope and it visualize observant portion widely as keeping high resolution.

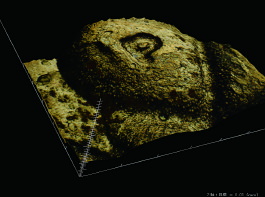

Stereo structure observation with high definition 3D

(Construct 3D image quickly by only simple mouse operation)

AR1260 takes in the both live-image and altitude data automatically, it can make “all focus image” and “3D image” easily. By combination of Z axis-auto-control-unit (Motorized), it can obtain “3D image”, “Depth compound image” and “3D profiling result” by simple mouse operation. Also, it can be slim down the work flow and remove human error so everyone can handle it easily.

* Wire frame indication

As dimensional image is indicated by wire frame, it makes possible the stereo structure indication not be affected by work surface, and simplify the 3D observation. Also, the dead angle produced by the work is covered.

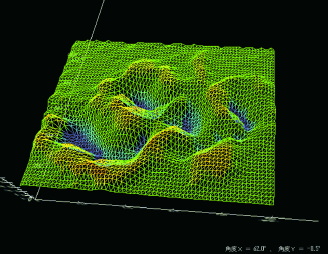

* Altitude is indicated by color

As altitude was replaced by color information, deference of altitude was obvious. It appeals to observer even if it’s subtle inclination. Also, it is possible to indicate the wire frame simultaneously.

* Simultaneous comparison of 3D images

It’s indicated 2 sheets of 3D images in parallel. Visual discrimination will become clear as it is possible to operate both angle and direction simultaneously. Furthermore, comparison observation could be easy because angle of sight could be expressed numerically.

* Measurement of cubic volume

It is possible to measure the cubic volume easily only by tracing the measured portion of the image after combining the 3D images.

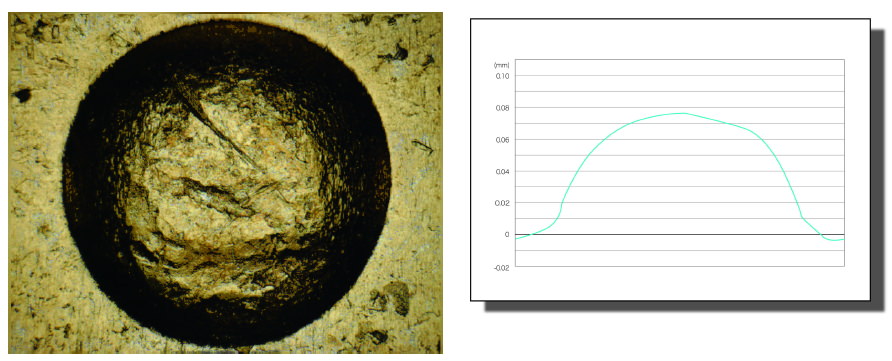

3D profiling function.

(Indicate the random section)

It is possible to obtain the curved line of section against nominal line mentioned on captured image. As it is decided the section while seeing the image, you can obtain necessary section profile surely. In addition to above, the altitude data could be seen in such Excel spreadsheet program so, effective use of data became easily so much than before.

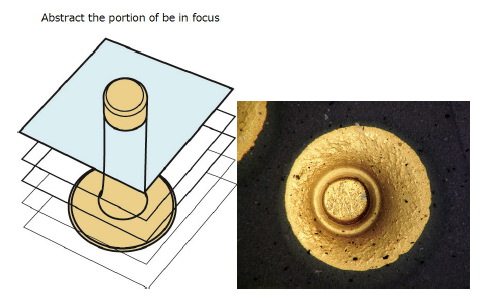

Quick depth composite function.

(This function can compose the depth while observing live image)

As this function abstract the image portions which are in true focus, and compose them later, this function finally compose total image which is all in true focus. Different from previous method which compose image files after taking photo, you can compose images while observing in real time so, it became easy to compose the desired image.

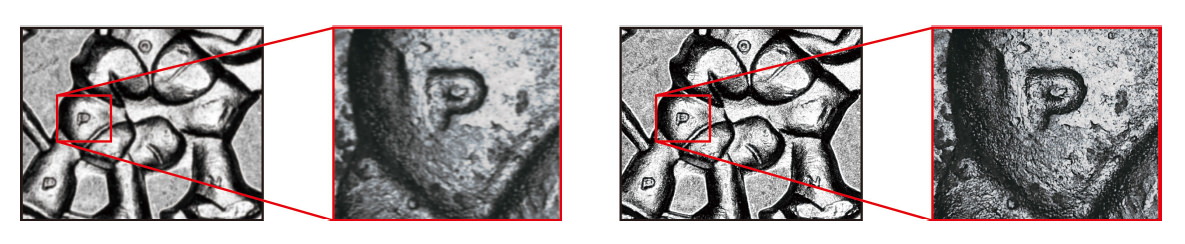

Compensation function for both vibration and camera shake.

(Cut the noise generated by vibration)

In the observation at ultra high magnification, subtle vibration or shaking which are not able to sense by human eye affect to image. We cut the micro vibration and improved the ultra high image so much in order to see finely and beautifully.

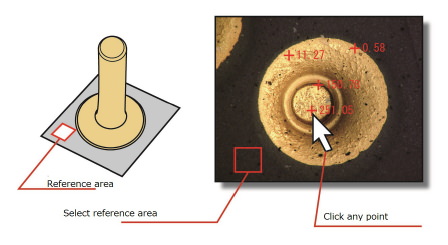

Reference position measuring function.

(Measure the altitude by referencing the random area)

Reference area (or reference line) should be designated at random position while confirming image on microscope which is in focus on whole area, and measure the difference of altitude against nominated reference position which would be indicated in the image. Only click the position you want to know the altitude, it attain the pinpoint measurement.

Operability pursued user-friendly

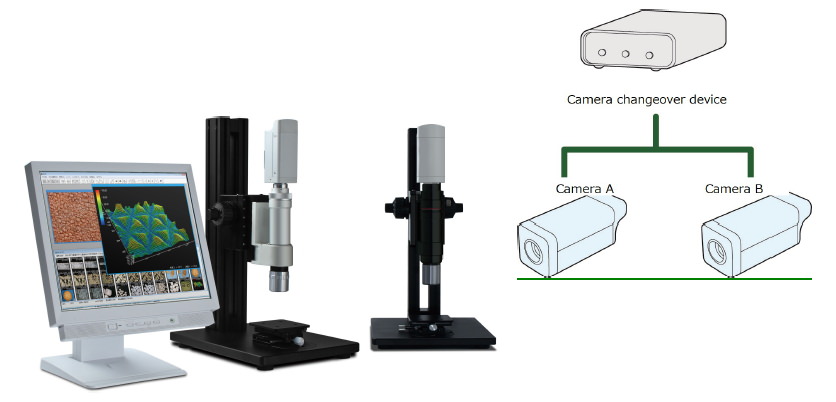

Dual camera system

(Possible to control after combining two cameras)

Our dual camera system let troublesome of lens exchange free. As it’s possible to connect two microscope cameras into one controller, the lens is guarded from sticking dust or damage produced during lens exchange work. The camera exchange can be done by one button which is easy operation. In case that you want to observe changing focal area frequently, as it can set both high magnification lens and low magnification lens simultaneously, you can handle it readily. It save time for lens exchange and shorten the observation flow so much.

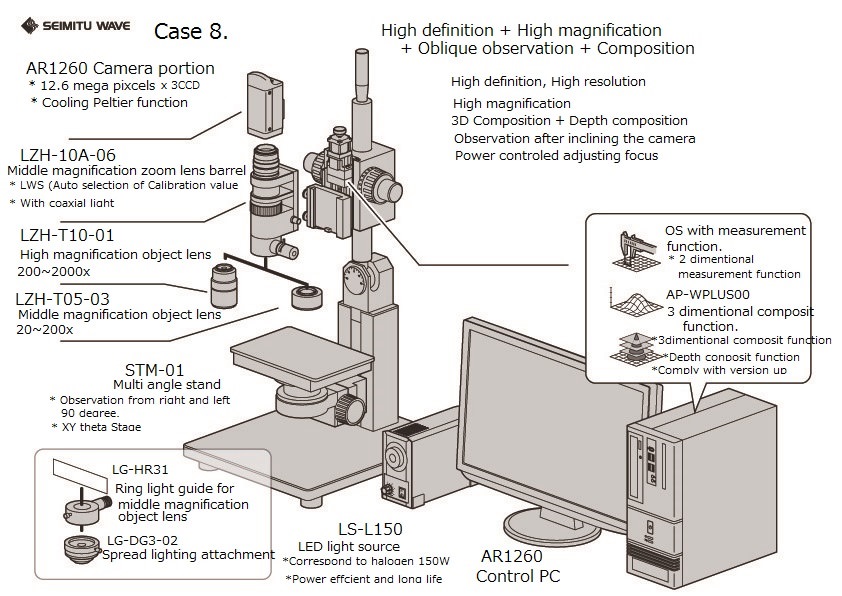

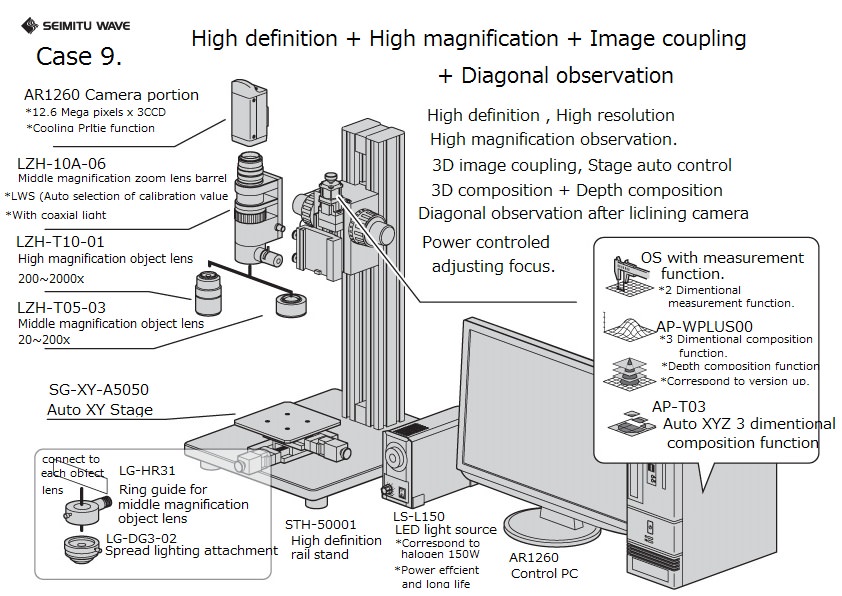

Abundant lens line up.

(Specialized for magnifying observation)

Lens line up are from low magnification to high magnification with high definition, and they are restrained distortion or aspherical aberration. These lenses are all cutting-edge technological assembly which can capture the clear image. Also they show powers on construction for “3D composite image”, “Depth composition” and “Magnifying observation” because it has high telecentricity.

LZM-10084

Micro Zoom Lens : Same magnification ➜ 50 times magnification

LZM-06075

Middle Magnification Zoom Lens : 45 times magnification ➜ 270 times magnification

LZH-10U15

High Magnification Zoom Lens : 90 times magnification ➜ 900 times magnification

LZH-10U30

High Magnification Zoom Lens : 180 times magnification ➜ 1,800 times magnification

LZH-10U50

High Magnification Zoom Lens : 300 times magnification ➜ 3,000 times magnification

LZH-10U70

High Magnification Zoom Lens : 420 times magnification ➜ 4,200 times magnification

LWS (auto calibration) function.

LWS is one of function which recognizes observing magnification automatically. When you change the lens magnification, it calls out fitted magnified calibration automatically. It’s not necessary to change the calibration whenever you change magnification so, human error would be nothing.

Excellent workability

The lens has enough working distance from low magnification to high magnification considering your workability. Prepared long working distance lens specialized for working distance as well. We propose appropriate function to match with the usage environment.

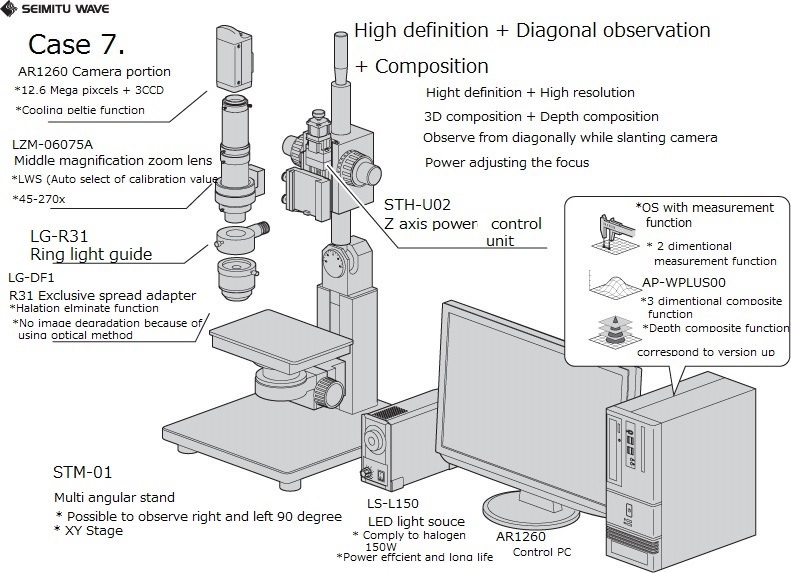

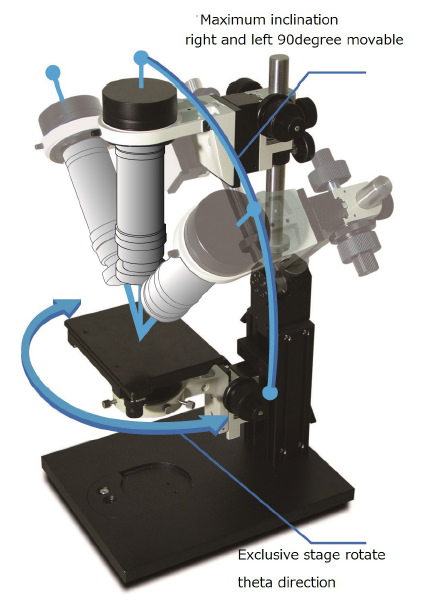

Multi angular observation stand.

(Can be observed from free angles within 180° )

This is exclusive stand which can be observed from different angle. It is possible to observe same point even if the angle is changed, and possible to incline the angle until maximum 90° to both sides. Without inclination of the observing object, make it possible the cubic observation without blind spot. As it is not through the mirror, image is not turned around, and you can observe from different angle without uncomfortable feeling. The exclusive stage can be moved to XYθ directions, and it’s possible to observe from 360° angle as well. As it’s fixing on lens, you can find out the best point quickly. Multi angular observation which can decide the observation point freely produce best observation environment.

Supporting in various observation method.

Eliminated the halation optically and cut the both dispersion and noise

As directive fiber light spread the light to all directions so it becomes uniform and softy illumination. Removal the halation by using image process technology had any problem like occurrence of noise so far but, we removed the halation optically in the model of AR1260. As a light hit on object equally, you can obtain glareless image without halation. It’s particularly effective for metal plate or solder which reflect hardly.

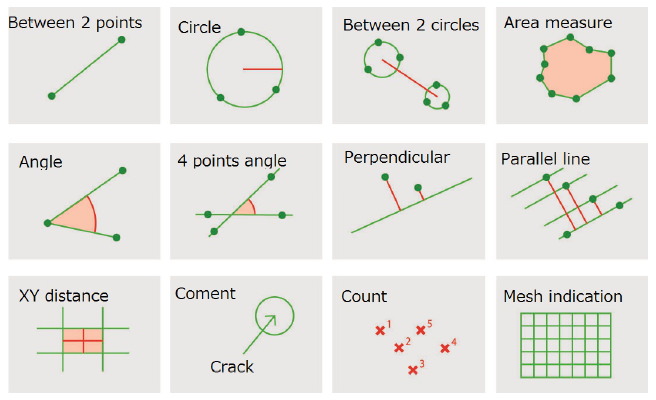

Taking measure while observing live image.

(Real time 2 dimensional measurement function)

Live measurement function which is possible to take measure on movie (Real time) or image data(Statics image) is packaged as standard equipment. We provided such various measurement functions as for “Distance between 2 points”, “Diameter”, “Interior angle”, “Polygonal area”, “Center distance between two circles” and so on. Only click by mouse, everyone can take measure speedy because of simple operation design. Measurement data can be stored with image data and also it can write by high multiplicity CSV form.

Various observation system

AR1260 equipped convenient functions which make operability and condition improve. It backup observation and measurement flow strongly.

* High accuracy zoom measurement.

In coordination with both digital zoom and measurement function, measurement point is designated while zooming. It’s possible to take measure precisely restraining an error or lag of measurement point.

* Pitch measurement function.

It’s possible to take measure after setting up nominal reference frame. From the setting up nominal referenced frame, you can take measure “Parallel pitch distance”, “Pitch radius of circle”, “Angle of straight line passing through reference frame”.

* Timer photographing

It’s possible to take photo by using timer at nominal time interval. Even if there is no worker on sight, it’s possible to take photo automatically. It became easy to observe troublesome shape change.

* Comparative indication function

It’s possible to indicate a number of images at same time. Live image under observing can be indicated at same time. And it’s also possible to do such following issues as “Good or bad judgment by comparison between live-image and stored image”, “Dimension error analysis by comparison measurement with other works”.

Put the adjustment focus into digital number.

Minimize errors among different works.

Digitalized focus match degree by focus indicator function. It’s possible to designate nominal point area and can adjust focus into zoom easily while observing. Focus condition was dependent on worker’s skill level so far but it can be systemized so, human error was minimized. The reproducibility when it’s necessary to observe same portion again was improved so much, which makes work-flow be effective so much.

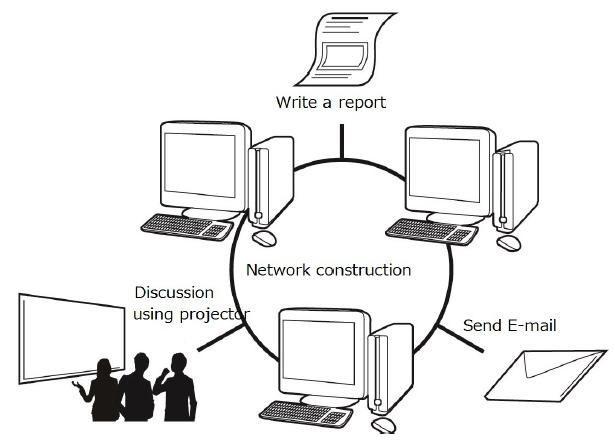

Conformity to Windows OS

You can observe using favorite PC.

This is conformity to Windows operation system. From “Measurement operation” to “letter input”, it supports observation and measurement work strongly. Everyone can use efficiently by graphical and friendly usability. Using both Digital-microscope and PC which you are accustomed to use make your working efficiency up so much. Image and measurement result can be pasted on Excel and Word directly so, you can arrange the report and submit it on the site of photographing. If you connect to Internet, you would be able to send it by e-mail.

It can be connected to optical microscope directly.

We never waste current equipments.

As we adopted a very versatile C Mount, it’s easy to connect to optical microscope directly at low cost. You can increase transaction of Cutting-Edge process without wasting old optical microscope lenses used before. Furthermore, by dual camera system (Function of camera change) you can hold both digital microscope and optical microscope in common.

* Lens for both Optical microscope and Digital microscope

* Other company’s microscope and new microscope

* Stereo microscope and Metallurgical microscope

By above combinations, you can create working environment which is optimized for usage purpose.